Been a while since I posted an update and a little bit has happened since then. On the car front, last time I posted about the Spiyda solid state voltage stabiliser that had improved the accuracy of my gauges. Unfortunately, after a few months it literally disintegrated. I don’t think it handled the bumps very well. This was only a few days before I had a decent drive planned so I went through my old parts and decided to fit up the original voltage stabiliser and to my surprise this worked better than the reproduction and showed the same readings as the Spiyda! For a little more comfortable drive around town I refurbished a set of 13 x 6 steel wheels that I had and fitted these up with 185/70/13 tyres. This has improved the ride out of sight and is now my go to for long country drives.

To try and address my suspension issues, I had GAZ build a set of longer pistons as my existing ones appear to be topping out and I had too much preload on the springs. They are apparently an easy job to fit up but someone must have a different definition of easy to me. A special tool had to be fabricated to remove them from the shocks and then it took two of us with lots of shock oil and patience to get them back together, primed and working again. They now work a lot better, but the knock is still there. Next stop will be different strut tops as that is all that’s left to try!

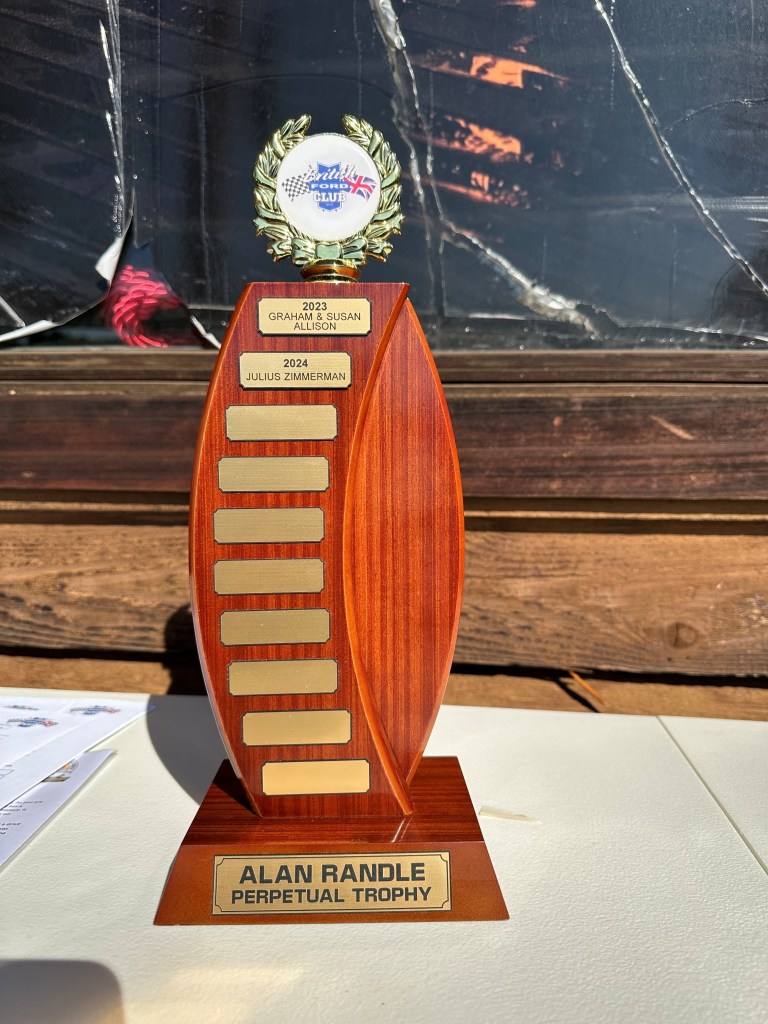

In May I attended the my car club, the British Ford Club of NSW, car show at the Ettamogah Hotel and I was thrilled to win the Allan Randle Perpetual Trophy for best car. This is a real honour and next year I will get to select the winner.

In October I attended the 3rd Cortina Nationals in Bathurst. Due to my job I couldn’t commit to attending until the week before but I registered, prepared the car and hoped for the best, which thankfully the week before I got the nod that I could go. While a lot of people trailered their car to the show, I decided to drive with Dad following me in my ute loaded with spares and cleaning products etc. Thankfully the weather was good, and we set off early. The drive was largely uneventful, albeit my car making a weird knocking sound that I chased the entire weekend. While annoying, it didn’t appear to affect performance, and I finally diagnosed it when I got home as a couple of loose exhaust manifold ones. The ones in the middle that are very difficult to get to on the GT. The entire weekend was fantastic and so well organised by my car club, the British Ford Club of NSW. Highlights of the weekend included a gala dinner on the Saturday Night and 170 Cortinas doing parade laps around Mt Panorama. We completely filled the circuit with Cortinas. On the Sunday we took over an entire street in Bathurst for the Show n Shine with over 230 cars on display. The weather was spectacular, and it was an amazing sight to see so many Cortinas in the one place. I was absolutely blown away when my car received the trophy for best Mk1 Cortina. What an absolute honour. As always, there’s still a list of things to work on but I’m slowly getting the car to drive a little nicer.

Hi Greg, long job.

I have two comments that might help.

1 I assume that the shocker issue is the front struts. I had a

knock on my suspension and found that the diameter of the foot of the

shock absorber is smaller than the inside diameter of the tube. It is

near impossible to tighten the retainer at the top sufficiently to stop

sideways movement in the tube.

I wrapped aluminium foil (air condition tape which is adhesive backed)

around the base which keeps the shocker firm in the strut and the noise

stopped. Unrelated but I also put some engine oil in the tube as when I

dismantled one strut there was signs of corrosion inside. it wasn’t a

problem with the original struts as they were oil filled, no cartridge

insert.

2 I replaced the bolts on the extractor with allen head bolts as

it was difficult to get a spanner on the hex head. I then cut the short

leg of an allen key down to about 10mm which fits nicely in the space

between the exhaust and the inlet manifold. Still a bitch to access and

best with an extension on the key but a lot better than the original hex

head bolts.

LikeLike

Thanks for the suggestion for the shocks, I’ll have a look.

i did the exact same thing with the manifold bolts. Changed to allen key bolts and can get an extra long allen key socket on them with an extension.

LikeLike